Managing a warehouse today is nothing like it was a decade ago. Volatile supply chains, fluctuating demand patterns, rising operational costs, and the pressure for real-time decision-making have pushed businesses small, medium, and large to rethink their inventory systems. In this landscape, Odoo Inventory Management has emerged as a practical and cost-effective ERP choice that warehouse teams find easy to adopt, scale, and rely on.

While many businesses want automation, accuracy, and transparency in their warehouse operations, not everyone has the budget for expensive ERP systems that demand heavy licensing fees and complicated setups. This is exactly where Odoo stands out. It offers a powerful, modular, and affordable solution that empowers businesses across industries to streamline their warehouse operations without worrying about skyrocketing software costs.

Whether you're managing a single warehouse or overseeing multiple facilities, this comprehensive guide will help you understand why Odoo has become the most cost-effective ERP solution for warehousing and how its modern inventory features help businesses cut costs without cutting functionality.

The High Cost of Traditional Warehouse ERP Systems (and Why They Fail Today)

For years, businesses relied on conventional ERP systems for warehouse management. These legacy solutions were often marketed as complete, enterprise-grade systems capable of managing even the largest operations. But over time, their limitations have become more visible.

1. High Licensing and Renewal Fees

Traditional ERP systems come with steep licensing fees, often followed by annual renewals. These costs quickly add up, making them tough for small and mid-sized warehouses to sustain.

2. Heavy IT Infrastructure Requirements

Many legacy systems require additional hardware, third-party integrations, or dedicated servers leading to extra maintenance, IT support, and infrastructure spending.

3. Limited Real-Time Visibility

Without accurate, synchronized data, teams struggle to track inventory movements. Stock discrepancies, delayed reports, and manual adjustments can easily lead to mistakes and added expenses.

4. Long Implementation Times

Some traditional ERPs require weeks (or months) of configuration and employee training. Businesses often face downtime or operational disruptions during this period.

5. Hidden Costs

Extra modules, integrations, support packages, and customizations often come with additional fees. What seems like a cost-effective deal at first gradually becomes an expensive, rigid environment.

It’s no surprise that businesses have started looking for alternatives that offer the same power without the heavy price tag. And this is where Odoo’s value becomes truly evident.

What Makes Odoo Inventory Management the Most Cost-Effective Choice?

Odoo has gained popularity among warehouse operations teams for its modern interface, automation tools, and transparent pricing model. But its real advantage lies in how efficiently it delivers value.

Transparent Pricing & Modular Flexibility

Unlike many ERPs that force businesses to purchase large bundles, Odoo follows a simple and flexible structure. You choose only the modules you need Inventory, Purchase, Accounting, Barcode, Manufacturing, or others.

This modular approach ensures that businesses don’t overspend on functionalities they will never use.

Low Maintenance and Faster Implementation

Odoo’s architecture is light, cloud-friendly, and easy to configure. Since the system integrates seamlessly with other Odoo Apps, you don’t need multiple vendors or complex middleware. This reduces both implementation time and long-term maintenance costs.

Many warehouses can go live within weeks, not months.

Built for ROI and Real-World Efficiency

Unlike heavy ERP systems designed with large corporations in mind, Odoo supports warehouses of all sizes. Its tools are built to deliver quick wins:

- Reduced data entry

- Fewer picking errors

- Optimized routes

- Better worker productivity

- Lower inventory carrying costs

In the long run, these small improvements translate into substantial savings.

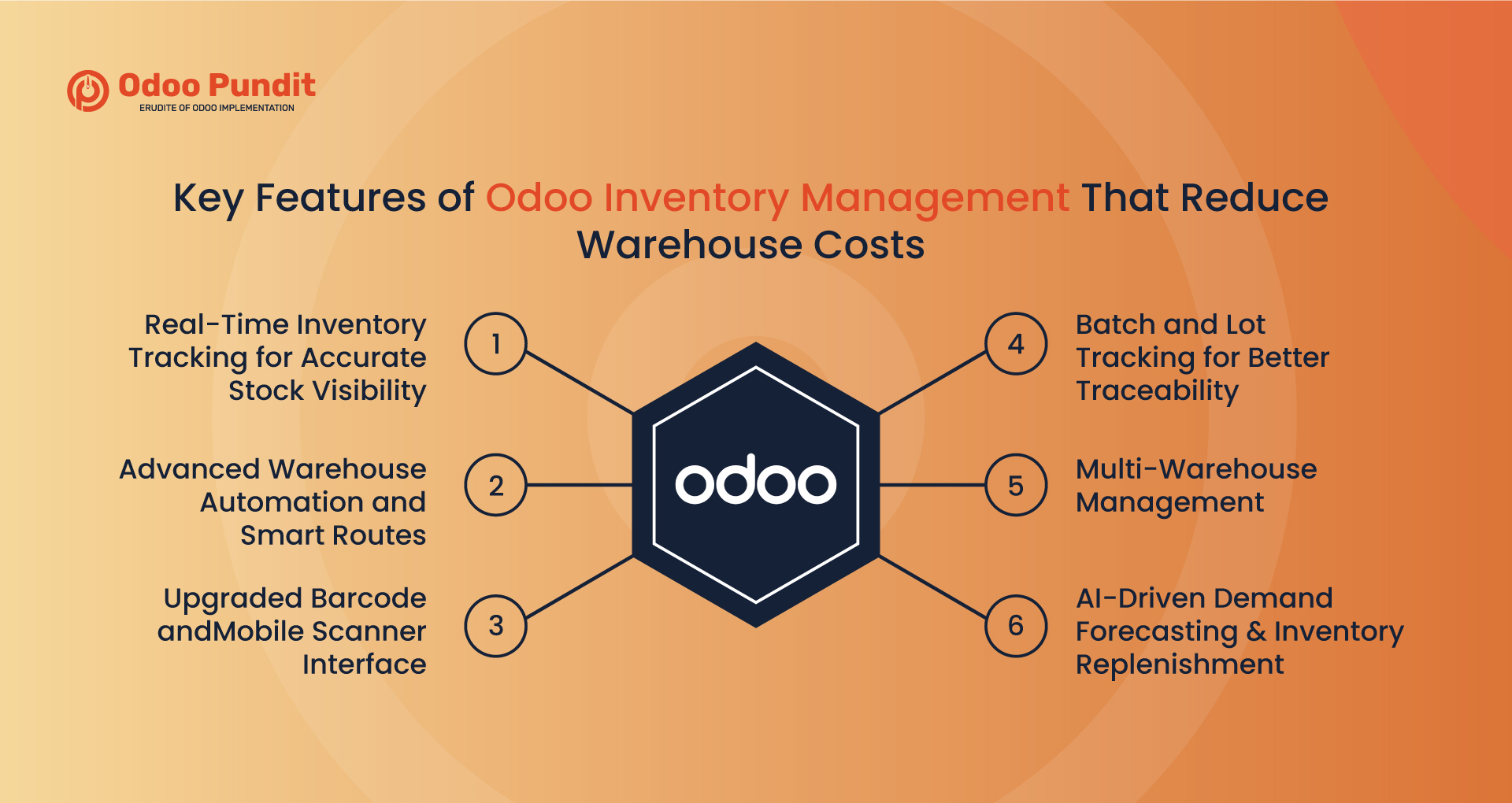

Key Features of Odoo Inventory Management That Reduce Warehouse Costs

Odoo continues to evolve each year, and the latest update (Odoo 19) introduced several enhancements focused on accuracy, automation, and scalability. While we won’t mention the version again, some of the newest features are essential to highlight.

Below are the most impactful Odoo inventory features that contribute to better warehouse operations and lower costs.

Real-Time Inventory Tracking for Accurate Stock Visibility

The system updates inventory quantities instantly, even during high-volume operations. This reduces the risk of overselling or underselling and helps teams make faster decisions. Enhanced dashboard metrics ensure every stock movement is traceable.

Practical benefits:

- Accurate stock forecasts

- Faster reconciliation

- Fewer manual adjustments

Advanced Warehouse Automation and Smart Routes

Odoo’s smart routing helps automate tasks like:

- Picking

- Packing

- Putaway

- Cross-docking

- Replenishment

Automated rules ensure stock moves smoothly through the warehouse without unnecessary manual intervention. This improves operational clarity and reduces labor hours.

Upgraded Barcode and Mobile Scanner Interface

Odoo’s barcode management system makes high-volume operations simple and error-free. The mobile interface helps workers process items quickly, even in areas with low or no connectivity.

Highlights:

- Faster scanning

- Paperless operations

- Reduced picking errors

- Smooth batch and wave picking

Batch and Lot Tracking for Better Traceability

Businesses handling perishable goods, spare parts, or regulated products rely on clear traceability. Odoo simplifies this with automated batch and lot tracking.

Teams can quickly identify:

- Expiring products

- Stock with quality issues

- Items needing recall

This significantly reduces compliance risks and ensures every product can be traced back to its source.

Multi-Warehouse Management

Managing multiple locations doesn’t have to be complicated. Odoo offers a unified platform where you can monitor:

- Stock availability

- Transfers

- Warehouse performance

- Routes and replenishment

For businesses expanding or operating multiple facilities, this centralized system is a major cost-saver.

AI-Driven Demand Forecasting & Inventory Replenishment

The forecasting engine uses past data, seasonal patterns, and current trends to predict future demand. Automated replenishment rules ensure the warehouse always has the right amount of stock without overloading shelves.

Expected Results:

- Reduced carrying costs

- Fewer stockouts

- Less wastage

How Odoo Inventory Management Reduces Warehouse Costs

Below is a clear view of how Odoo helps warehouses save money through automation and better accuracy.

Cost Factor | Traditional Systems | With Odoo |

Licensing Costs | Expensive bundles | One app free, use based, affordable pricing |

Setup Time | Long, complex | Quick and simple |

Hardware Needs | High | Minimal |

Stock Accuracy | Prone to errors | Real-time tracking |

Labor Costs | High manual work | Automated workflows |

Operational Visibility | Limited | Real-time dashboards |

Scalability | Costly | Easy and inexpensive |

Reduces Human Errors

Barcode automation and smart operations minimize manual data entry, lowering the chances of errors that often lead to rework, losses, or customer complaints.

Prevents Stockouts and Overstocking

Demand forecasting and replenishment help maintain the right stock levels. This improves sales performance and reduces wasted inventory.

Streamlines Warehouse Labor

Optimized workflows reduce picking time, improve worker productivity, and eliminate unnecessary movement around the warehouse.

Improves Space Utilization

Smart putaway rules ensure inventory is stored in optimized locations, improving warehouse flow and saving space.

Cost Comparison: Odoo Inventory vs Other ERP Solutions

Many businesses compare Odoo with traditional ERPs before switching. Here’s a simplified view:

Feature | Traditional ERPs | Odoo Inventory Management |

Cost | High | Affordable |

Scalability | Complex | Easy |

Customization | Expensive | Flexible |

Real-Time Tracking | Limited | Strong |

Automation | Moderate | Extensive |

Implementation Time | Long | Short |

Integration | Often costly | Native and seamless |

Overall, Odoo delivers more value for the cost, especially for businesses looking for warehouse optimization without making heavy investments.

How Odoo Inventory Management Works (A Simple Workflow)

Here’s a step-by-step example of how Odoo supports daily warehouse operations:

- Receive Items

Use barcode scanning to receive products into the system instantly. - Putaway Rules Trigger

Smart routes guide staff to the right storage location based on product type, demand, or picking strategy. - Pick-Pack-Ship

Workers follow clear picking paths, improving speed and accuracy. - Replenishment Rules Kick In

When stock reaches reorder levels, purchase orders or manufacturing orders are triggered automatically. - Reporting & Analytics

Managers gain insights into turnover rates, product demand, performance metrics, and more.

This workflow is simple, efficient, and suitable for warehouses of all sizes.

Is Odoo a Good ERP for Warehouse Management? (The Final Verdict)

Absolutely.

Odoo is one of the most reliable, scalable, and cost-effective inventory solutions available today. It suits:

- Small warehouses needing automation

- Mid-sized operations scaling rapidly

- Large multi-warehouse businesses

- Logistics and distribution companies

Its strengths lie in its adaptability. Whether you need forecasting, barcode automation, multi-warehouse control, or detailed traceability, Odoo provides a robust platform to build on. And with the support of professional Odoo implementation and Odoo customization, businesses can enhance the system further and tailor it to their exact operational needs. inv

Real Use Cases: How Warehouses Achieve High ROI with Odoo

Warehouses using Odoo report clear, measurable improvements:

- 30–50% reduction in picking errors

- 25–35% improvement in operational speed

- 20–30% reduction in inventory carrying costs

- Faster cycle counts and reconciliations

- Higher worker productivity and visibility

These numbers reflect what many businesses experience once they move away from manual or outdated ERP processes.

FAQs

1. Why is Odoo Inventory Management considered cost-effective?

Because of its modular structure, affordable pricing, and automation-driven tools that reduce manual effort, errors, and operational waste.

2. What new inventory features support warehouse optimization?

Enhanced tracking, improved barcode tools, smarter replenishment, and better automation features all contribute to cost savings.

3. Can Odoo support multiple warehouses?

Yes, it can manage multiple locations, transfers, and stock movements from one central platform.

4. How does Odoo compare with other ERP systems?

It offers similar capabilities but with faster implementation, greater flexibility, and significantly lower costs.

5. Is Odoo suitable for smaller warehouses?

Yes. Its modular system allows smaller operations to start small and scale gradually as they grow.

Ready to Transform Your Warehouse Operations?

If you're searching for a scalable, affordable, and modern solution to streamline your warehouse, Odoo Inventory Management is a smart choice. It’s flexible, cost-effective, and designed to grow with your business.