If you run or manage a cosmetics manufacturing operation, you know how much pressure sits on traceability. Every raw material, every batch, and every finished product must be accounted for. When an auditor asks where an ingredient came from or a customer reports an issue, you need clear answers fast not scattered spreadsheets or guesswork.

Odoo for cosmetics manufacturing plays a key role in helping growing manufacturers bring structure, visibility, and consistency to batch tracking across purchasing, production, quality, and distribution all within one connected system, provided the right settings and workflows are in place.

In this guide, we’ll explain how batch traceability works in Odoo, what it looks like in day-to-day operations, and what to consider if you’re evaluating it for your business.

Based on years of real manufacturing implementations, most traceability challenges come from configuration discipline and process consistency rather than software limitations.

What You’ll Learn in This Guide

- How Odoo tracks batches across purchasing, manufacturing, quality, and deliveries

- What configuration is required for reliable lot traceability and compliance

- How expiry management, recalls, and audit trails work in practice

- Where automation helps and where operational discipline still matters

- Common implementation mistakes and how to avoid them

Quick Summary: How Odoo Handles Batch Traceability

- Lots must be enabled globally and configured per product

- Supplier batch information is captured at receipt

- Manufacturing links raw material lots to finished batches through BOMs and work orders

- Quality inspections are driven by quality control points and validation rules

- Expiry dates support FEFO removal strategies and alerts

- Deliveries retain batch visibility for forward traceability

- Traceability reports enable forward and backward traceability for audits and recalls

This foundation creates full lot genealogy across the product lifecycle.

Why Batch Traceability Matters in Cosmetics Manufacturing

Cosmetics manufacturing operates in a regulated environment where product safety and consistency are non-negotiable. Traceability is not just a compliance exercise, it directly impacts risk management, brand reputation, and operational stability.

Regulatory Expectations and Audits

Manufacturers must be able to demonstrate:

- Which supplier provided each ingredient

- Which batch of raw material went into each finished product

- When production occurred and under what conditions

- Who approved quality checks and releases

Auditors expect clean records, consistent processes, and fast access to historical data. When information lives in emails, paper logs, or disconnected systems, audits become stressful and error-prone.

Business Risks of Weak Traceability

Poor traceability creates real exposure:

- Slow recalls when affected batches can’t be isolated quickly

- Increased waste due to over-quarantining inventory

- Manual errors from repeated data entry

- Loss of trust with customers and partners

As production volumes grow, these risks multiply. Automation combined with disciplined processes becomes essential.

What Batch Traceability Means Inside Odoo

Traceability in Odoo is built around the idea that every physical movement carries a digital identity. That identity follows the product from intake through manufacturing and shipment but only once lot or serial tracking is enabled and products are configured correctly.

Lots and Serial Numbers Explained

For cosmetics, batch tracking typically uses lot numbers rather than individual serial numbers. A lot represents a group of units produced or received under the same conditions.

Each lot can store:

- Supplier reference

- Manufacturing date

- Expiry date

- Quality status

- Internal notes and documents

These fields support audit trails and long-term traceability.

How Modules Work Together

Odoo connects operational areas, so traceability flows naturally:

- Purchasing captures supplier and batch information

- Inventory manages locations, movements, and removal strategies

- Manufacturing links consumed lots to finished batches through BOMs and work orders

- Quality records inspections and approvals

- Sales records which customers received which batches

Instead of separate databases, everything lives in one system, creating full product genealogy.

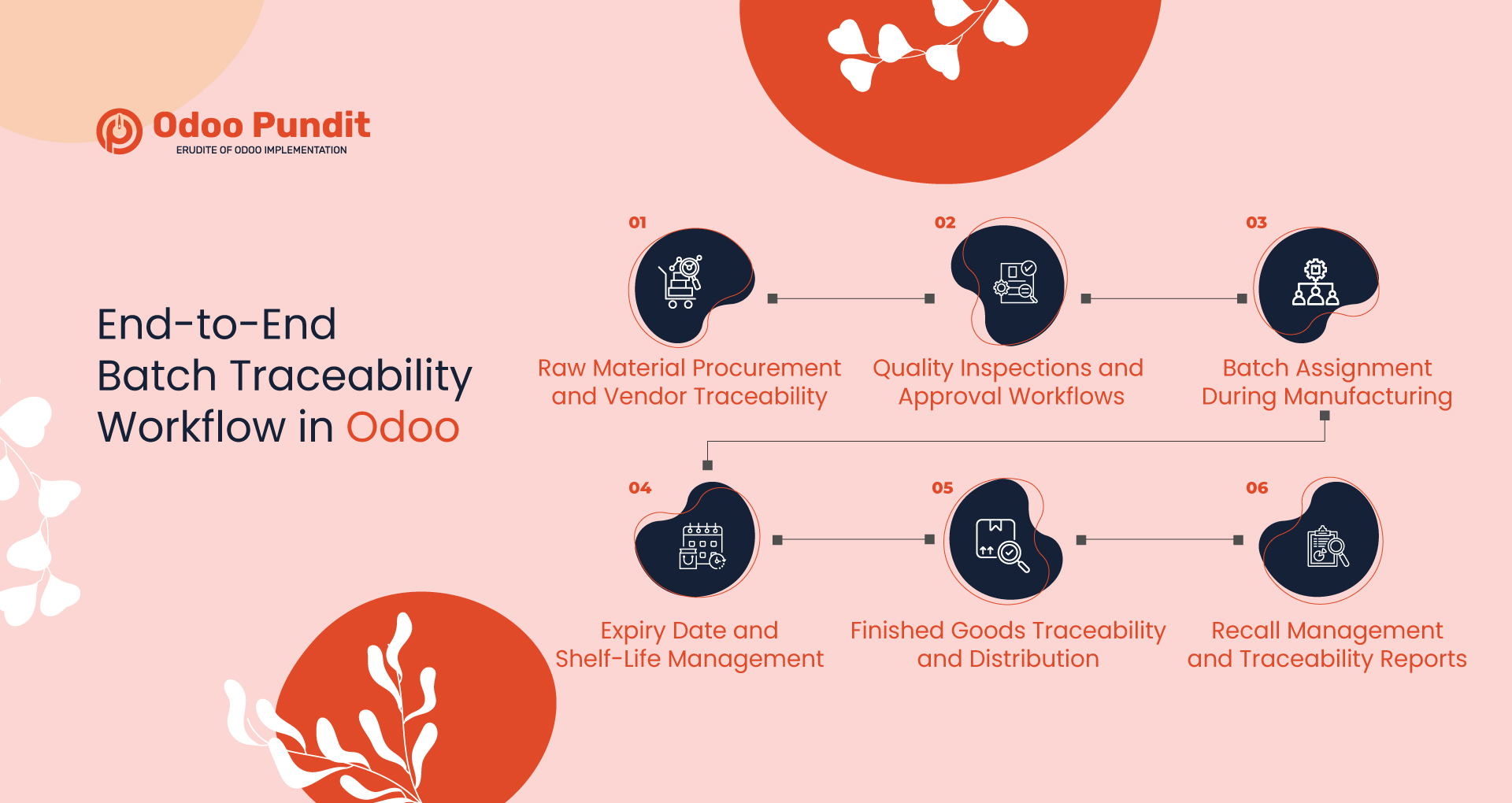

End-to-End Batch Traceability Workflow in Odoo

Below is how traceability typically works once lot tracking, expiration handling, and quality workflows are configured.

Important note: Before batch traceability becomes operational, manufacturers must enable lot or serial tracking in inventory settings and configure products accordingly. Expiration dates, quality checkpoints, and reporting visibility also require setup at the product and process level.

Raw Material Procurement and Vendor Traceability

When purchasing teams receive materials, Odoo can capture supplier references and lot numbers at receipt as long as Lots & Serial Numbers is enabled and the product is set to lot tracking, so the receipt flow prompts users to assign lots before validation.

Each receipt builds transaction history showing which supplier delivered which material and when. Deeper insights such as supplier quality trends or rejection analysis depend on how quality checks and reporting dashboards are configured.

Barcode scanning can be used to speed up lot capture and movements when barcode operations are enabled and devices are configured, reducing manual errors and improving warehouse efficiency.

Quality Inspections and Approval Workflows

Incoming materials and production steps trigger quality checks based on predefined rules. Quality teams record measurements, observations, and attachments directly against each batch.

Quality checks can generate alerts, validations, and follow-up actions when inspection criteria are not met. Whether a failed inspection blocks the next operational step depends on how quality control points and validation rules are configured. Without enforced workflows, results may be recorded while operations continue.

In cosmetics, many teams use a simple “quarantine → approved → released” discipline so only approved lots are available for production and dispatch. This supports controlled stock locations and reduces risk exposure.

Batch Assignment During Manufacturing

During production, raw material lots are consumed and linked directly to the finished batch. This linkage forms the core of traceability.

If a finished product later shows an issue, teams can trace backward to identify:

- Which ingredient lots were used

- Which BOM and work order produced the batch

- When production occurred and who executed it

This enables precise root-cause analysis.

Expiry Date and Shelf-Life Management

Cosmetic products are sensitive to shelf life. Expiry dates can be tracked at the lot level once expiration settings are enabled.

FEFO (first-expiry-first-out) removal strategies help reduce waste and prevent expired shipments. Alerts can notify teams when products approach expiry once Expiration Dates is enabled and alert or removal dates are maintained on lots.

Finished Goods Traceability and Distribution

When products ship to customers, traceability continues through delivery operations.

Batch details appear on delivery documents only when lot tracking is enabled at the product level. These preserves forward traceability and support customer-level investigations when needed.

Recall Management and Traceability Reports

Traceability reports enable both forward and backward traceability. Teams can isolate affected batches, identify impacted customers, and document corrective actions.

These reports provide the data required for recalls, while execution still depends on operational response and coordination.

How Automation Improves Control and Accuracy

Manual processes are often the weakest link in traceability. Automation reduces dependency on individual memory and disconnected files.

Automated Purchasing and Replenishment

Reordering rules help maintain optimal stock levels while preventing excess inventory. Vendor lead times and historical consumption data support planning.

Digital Approvals and Audit Trails

Approval workflows capture who approved what and when, when approval rules are enabled for relevant operations.

Odoo logs transaction timestamps across inventory, manufacturing, and quality activities. Quality checkpoints and inspection results are recorded only when quality control points and validation rules are configured.

Real-Time Operational Visibility

Standard reporting views (list, pivot, and activity views) provide insight into inventory levels, expiring lots, production status, and quality exceptions. Deeper KPI dashboards are typically configured based on business needs.

Many teams centralize stock operations using tools like Odoo inventory, connecting warehouse movements with production and sales workflows.

Business Benefits of Using Odoo for Cosmetics Manufacturing

Faster Audits and Recall Readiness

Structured data simplifies audits and incident investigations.

Reduced Waste and Operational Errors

Expiry controls and scanning workflows reduce mispicks and write-offs.

Stronger Vendor Accountability

Batch history supports objective supplier discussions.

Scalable Process Discipline

Standardized workflows scale as volumes grow.

Common Mistakes When Implementing Traceability in Odoo

- Not enabling lot tracking consistently across products

- Poor product master data and naming conventions

- Missing quality control points on critical steps

- Weak user training on scanning and validation

- Inconsistent governance on quarantine and releases

Avoiding these early saves significant remediation later.

Implementation Considerations for Cosmetics Manufacturers

Data Setup and Governance

Clear standards prevent reporting gaps and audit risk.

Training and User Adoption

Users must understand why accuracy matters.

Customization and Integration Needs

Some operations require tailored flows. In such cases, Odoo customization services may help align workflows.

Long-Term Scalability and Support

Structured rollout planning and reliable Odoo implementation services support long-term consistency.

Is Odoo the Right Fit for Your Traceability Needs?

Odoo works well for manufacturers that:

- Want an integrated platform

- Need scalable traceability without heavy infrastructure

- Prefer configurable workflows

Highly regulated environments may require deeper governance design.

Final Thoughts

Strong traceability isn’t just about passing audits. It enables predictable operations, controlled risk, and scalable growth. When configured correctly, Odoo provides a practical framework for connecting suppliers, production, quality, and customers into one transparent system.

Start by identifying your current gaps and operational risks. A clear understanding of workflows will determine how effectively Odoo can support your traceability goals.

Frequently Asked Questions

Yes. Expiry dates are stored at the lot level once expiration tracking is enabled, allowing FEFO rules and alerts to operate.

Audit trails, traceability reports, and quality records support audits when workflows are properly configured.

Website may use cookies to personalize and facilitate maximum navigation of the User by this site. The User may configure his / her browser to notify and reject the installation of the cookies sent by us.

Yes. Finished batches maintain links to consumed raw material lots, enabling backward traceability.

Traceability reports quickly identify affected batches and customers, but execution depends on operational coordination.

Purchasing, inventory, manufacturing, quality, and sales all contrib